The sugarcane sugar making equipment in the sugar factory mainly includes sugarcane flippers, conveyors, presses, sugar suction filters, and other sugarcane sugar making machinery and equipment

The process in which sugarcane is used as raw material in a sugar factory to produce white sugar, crude sugar, and other products through processes such as juice extraction, purification, evaporation, crystallization, honey separation, and drying. The characteristics of sugarcane, the chemical composition and properties of sugarcane juice have a significant impact on the sugar making process, and are the basis for selecting production methods and process conditions.

Steps of sugarcane sugar production process in sugar mills

The sugar production process of sugarcane includes juice extraction, purification, evaporation, crystallization, honey separation, and drying. The process technology of the last four steps is basically the same as that of sugar beet production.

Juice extraction

There are two methods for extracting sugarcane juice: pressing and exudation. The squeezing method is a method of extracting sugarcane juice by combining pre-treatment and squeezing equipment with infiltration systems. The exudation method is a method in which sugarcane is pre treated and crushed, and through the use of exudation equipment and a certain juice flow system, the sugarcane material is infiltrated with water and dilute sugar juice to continuously leach and wash out the sugarcane sugar content.

Sugarcane pressing method

The principle of squeezing and extracting juice is mainly to cut sugarcane into filamentous and sheet-like sugarcane materials, and feed them into a press, causing the cell wall of sugarcane cells filled with juice to rupture under the pressure of the press roller and oil pressure. The sugarcane material is compressed, and the cells are flattened while the juice is discharged; By using the infiltration system, the expanded bagasse discharged from the press is added with water or diluted with juice to dilute the sugar content inside the cells and extract more sugarcane juice.

Sugarcane is pressed multiple times through several three roll presses. Add water for infiltration before the sugarcane enters the final press. The added water is called infiltration water, and the general dosage is 15-25% of the amount of sugarcane. The juice extracted from the last press is called the last press juice, which is then pumped into the previous press as the leachate. The sugarcane material that enters the press is infiltrated, and the squeezed juice is then used as the leachate from the previous press until it reaches the second press. This is the commonly used compound infiltration method in sugar factories. The juice squeezed from the previous and second presses is combined into a mixed juice and sent for purification treatment. The sugarcane material discharged from the last press is called bagasse. The moisture content in bagasse is 45-50%, sugar content is 1-4%, fiber content is 45-52%, and soluble solids are 1.5-6%. Bagasse is sent to boilers as fuel or used as other industrial raw materials. The sugar extraction efficiency of the juice extraction method is measured by the sugar extraction rate, which is defined as the mass percentage of sucrose extracted from sugarcane to the sucrose in the sugarcane. The sugar extraction rate of sugarcane mills is between 92% and 97%.

The main equipment for squeezing and extracting juice includes sugarcane cutters, presses and their driving devices, infiltration systems, and corresponding conveying equipment. The sugarcane cutter consists of a cane cutter and a driving device. The press machine consists of three rollers and a frame. The rollers of the three roll press are embedded into a triangle and are called the top roller, front roller, and rear roller depending on their position. There is a certain gap between the top roller and the front and rear rollers. The shaft ends of the three rollers are equipped with transmission teeth, and the top rollers are driven by a reduction device by a prime mover such as an electric motor, steam turbine, or steam engine, so that the three squeezing rollers rotate at the same speed.

The production capacity of a sugarcane factory is expressed in terms of the daily crushing of sugarcane by the factory. The ability to handle sugarcane is related to factors such as the number of crushing machines, sugarcane crushing degree, diameter and length of the crushing rollers, roller speed, sugarcane fiber content, and requirements for sugar extraction. Usually, sugar mills use 4-6 presses to form a row of presses. Two or three columns are also used to meet production needs.

The chemical composition of sugarcane juice varies with the chemical composition of sugarcane, storage time after harvesting, and environment. Table 1 [Cane Juice Composition] shows the chemical composition of sugarcane juice.

Since the late 1980s, sugarcane juice extraction technology has tended to strengthen sugarcane pretreatment, increasing the crushing degree to 70-80%; Pay attention to using a high-level feeding groove or a pressure feeding roller (also known as a toothed feeding roller) to form a five roll press with two traditional three roll presses, in order to strengthen the feeding of the press and perform pre compression, thereby improving the production capacity of the press; On the other hand, in the infiltration process, on the basis of the compound infiltration system, the majority of the dilute juice from the press is refluxed back to the main press, increasing the infiltration amount without increasing the infiltration water amount, making the bagasse liquid content reach saturation, showing saturated infiltration, fully infiltrating and diluting the residual sugar content of the sugarcane material, and achieving the goal of further improving sugar extraction.

The squeezing method consumes a lot of steel and electricity, but it has the advantages of strong adaptability to sugarcane processing, convenient technical management, and reliable operation, making it still the main method for sugarcane juice extraction so far.

Sugarcane flipper, conveyor, press, sugar suction filter and other sugarcane sugar making equipment

The content of this article is sourced from the internet and is not related to graphics or text

Sugarcane flipper conveyor

Sugarcane flipper conveyor

Sugarcane Juicing Machine Sugarcane Sugar Factory Juicing Machine

Sugarcane Juicing Machine Sugarcane Sugar Factory Juicing Machine

Sugarcane middle rake tooth conveyor

Sugarcane middle rake tooth conveyor

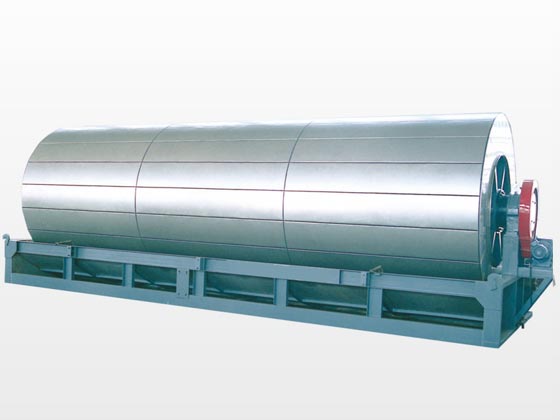

Vacuum suction filter without filter cloth, sugarcane sugar making suction filter

Vacuum suction filter without filter cloth, sugarcane sugar making suction filter

Automatic sugarcane unloading conveyor

Automatic sugarcane unloading conveyor

Sugarcane impurity remover

Sugarcane impurity remover

Vacuum suction filter without filter cloth

Vacuum suction filter without filter cloth

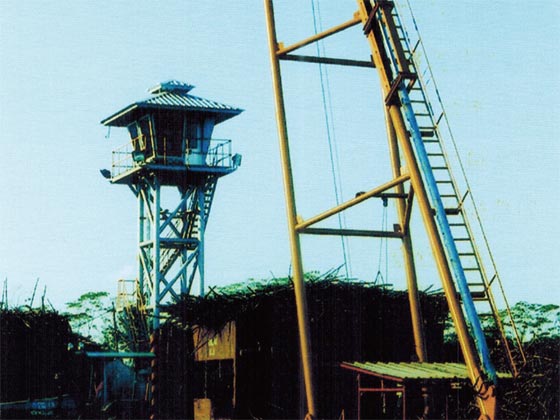

Cane unloading mast machine

Cane unloading mast machine

Sugarcane sampling machine

Sugarcane sampling machine

Juice steam valve

Juice steam valve

Cane juice drum sieve

Cane juice drum sieve

vibrating screen

vibrating screen

The above is the relevant content of Guangdong Zhenghe Machinery Network about sugarcane sugar making equipment in sugar factories, including sugarcane flippers, conveyors, presses, sugar suction filters, and other sugarcane sugar making machinery equipment. If you want to learn more about rubber processing equipment, sugarcane sugar making equipment exploration, design, production, production, installation, debugging, maintenance, and repair information, please feel free to contact the business specialist of Guangdong Zhenghe Machinery Co., Ltd. via WeChat or phone. Zhenghe Machinery will warmly serve you. Service hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Website: http://m.mangobuy.cn/html/jsjl/195.html

Reminder: Guangdong Zhenghe Machinery relies on new technologies, processes, and products for development, and the manufacturing of equipment strictly follows product manufacturing standards. To improve the quality of the product, the main components such as motors, gearboxes, electrical appliances, bearings, seals, etc. are purchased from imported parts or high-quality domestic brands. The company's processing equipment includes CNC gantry boring and milling, automatic cutting and forming machines, shot peening and painting production lines, and heat treatment production lines. The average technical level of enterprise employees is level 6, and the installation and after-sales service team is good, meeting the various needs of various customers. Customized mode, providing one-stop services for on-site exploration, design, production, production, installation, and debugging according to the actual needs of customers. Business consultation hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Copyright © m.mangobuy.cn